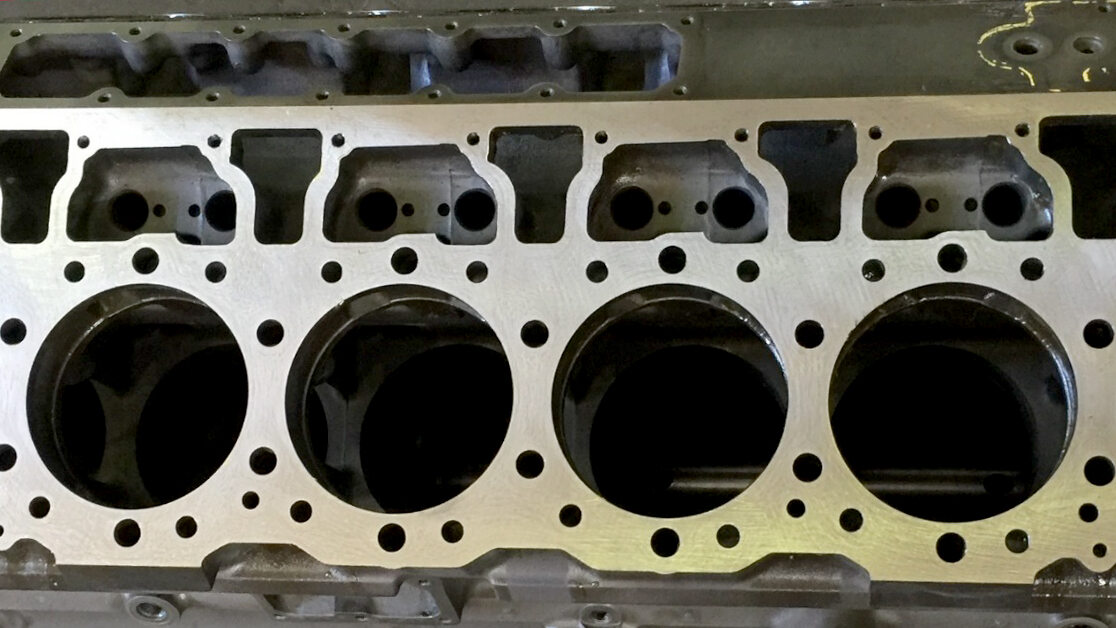

Injin Silin Injin Layiner da Piston Zobe sune nau'i-nau'i daga nau'ikan tashin hankali da suka yi aiki a karkashin high zazzabi, babban matsin lamba, madadin kaya da lalata. Yin aiki a cikin hadaddun da kuma canji yanayi na dogon lokaci, sakamakon shine na'urar sayen siliki kuma an lalata shi, wanda ke shafar wutar lantarki, tattalin arziƙi da rayuwar injin. Yana da matukar muhimmanci a bincika abubuwan da ke haifar da layin silima yana jingina da lalacewa don inganta tattalin arzikin injin.

1. Dalilin bincike na na'urar silima

Halin aiki na lilin silima lilin, kuma akwai dalilai da yawa na sutura. Ana ba da izinin suturar al'ada saboda dalilai na tsari, amma amfani mara kyau da kiyayewa zai haifar da rashin daidaituwa.

1 SANAR DA CIKIN SAUKI CIKIN SAUKI

1) Yanayin lubrication bai da kyau, saboda sama da na sama na na'urar silima yana sawa da gaske. A na sama na silima liner yana kusa da ɗakin konewa, zazzabi yana da girma sosai, kuma yanayin lubrication yana da talauci sosai. Kusancin da Ruwa na iska da ba a bayyana ba da mai lalacewa na babban yanayin, wanda ya sa siliki yake cikin yanayin bushewa ko ɓataccen sa a kan silinda na sama.

2) ɓangaren ɓangaren yana ƙarƙashin matsin lamba, wanda ya sa silinda yake nauyi a saman da haske a kan ƙananan. An matso murfin piston a hankali akan bangon silima a ƙarƙashin aikin nasa na zamani da matsin lamba. Mafi girman matsin lamba, mafi wuya da samuwar da kiyaye lubricting na fim din mai, da kuma muni da na inji sa. A cikin Stroke aiki, kamar yadda piston ke sauka, matsin lamba mai kyau a hankali yana raguwa, don haka silinda yake satar silinda ya yi nauyi da haske.

3) acid na ma'adinai da kwayoyin halitta suna yin silinda na silinda kuma suna cike. Bayan konewa na ruwan hoda a cikin silinda, tururin tururi da acid ana haifar da ruwa a saman silsion, wanda ke narke cikin ruwa don samar da rikon pistiner, wanda ke narke cikin ruwa don samar da nakasar pisting, wanda ke narke cikin ruwa don samar da lalata.

4) Shigar da impurities na inji, saboda tsakiyar sakin silinda. Dust a cikin iska, impurities a cikin lubricating mai, da sauransu, shigar da piston da bango na silinda yana haifar da suturar fitina. Lokacin da ƙura ko impuritation ramuka a cikin silinda tare da piston, saurin motsi shine mafi girma a tsakiyar silinda, wanda ke ƙara suttura a tsakiyar silinda.

2 sayan lalacewa ta hanyar amfani mara kyau

1) tasirin tasirin tace na lubricating tlricating tace matalauta. Idan filayen mai ba ya aiki yadda yakamata, man lubricating ba zai iya tace sosai, da mai da mai dauke da yawan barbashi ba makawa na ciki na lineriner Liner.

2) Rashin girman tace iska. Matsayin iska shine cire ƙuraje da yand bar da ke cikin iska yana shigar da silinda don rage suturar silinda, piston da sassan piston. Gwajin ya nuna cewa idan injin din bai sance shi da injin iska ba, wanda ke sa silinda zai karu sau 60. Ba a tsabtace ta iska ba, kuma tasirin tacewa ba shi da kyau, wanda zai hanzarta sanya layin silima.

3) dogon lokaci kan zafin jiki na zafi. Gudun a ƙarancin zafin jiki na dogon lokaci, wanda ya sa baancin ɗaukakar carmin, ya fara yaduwa daga ɓangaren satar silin, yana haifar da mummunar suttura a saman ɓangaren lilin. Na biyu shine haifar da lalata elecakami.

4) Sau da yawa suna amfani da mai ƙazanta mai. Wasu masugidan don adana kuɗi, galibi a kan shagon mai da ba bisa ƙa'ida ba don siyan daskararren mai, wanda ya cika shi sau 1-2 ya fi girma 1-2 sau Fiye da darajar al'ada.

3 sayan lalacewa ta hanyar tabbatarwa mara kyau

1) Rashin Cutar Cutar Cutar Schproper Lantarki. Lokacin shigar da na'urar sayen silima, idan akwai kuskuren shigarwa, layin cibiyar silima, layin cibiyar silinda da crankshaft ɗin ba a tsaye ba, zai haifar da saurin silima.

2) Haɗa kusurwar jan rami. A cikin gyara, lokacin da haɗin ya haɗa kananan hannayen riga jan ƙarfe, wanda zai kuma haifar da abin da ya dace da kayan satar kayan silima.

3) Haɓaka sandunan lanƙwasa sanda. Saboda hatsarin mota ko wasu dalilai, mai haɗawa da sanda zai tanƙwara da lalacewa, kuma idan ba a gyara shi ba, zai iya hanzarta amfani da suturar silima.

2. Matsayi don rage silinda

1. Fara da farawa daidai

Lokacin da injin din yake sanyi, saboda ƙarancin zafin jiki, babban dankan mai da ƙarancin haske, famfo mai ba shi da isarwa. A lokaci guda, mai a kan bango na silinda yana gudana ƙasa da silinda silinda bayan tsayawa a cikin aikin al'ada, wanda ya haifar da kyakkyawan bangon silinda lokacin farawa. Saboda haka, lokacin da farawa a karon farko, ya kamata a ba da injin din don laps, da kuma tashin hankali ya kamata a sa shi kafin farawa. Bayan farawa, ya kamata a sami aikin idle sama, an haramta shi sosai don girgiza mai mai, sannan kuma ya fara lokacin da yawan zafin jiki ya kai 40 ℃; Fara yakamata ya bi zuwa sanyin kaya mai saurin gudu, kuma mataki-mataki kowane kaya don fitar da nesa, har sai yawan zafin mai ya zama al'ada, na iya juyawa zuwa tuki na al'ada.

2. Sayi daidai na lubricating mai

Don tsananin goyon bayan kakar wasa da kuma abubuwan injin don zaɓar mafi kyawun ƙimar mai, kuma sau da yawa ana bincika su da ƙimar mai da ingancin mai.

3. Tabbatar da kula da matatar

Tsayawa tace iska, tace mai da mai da mai a cikin kyakkyawan yanayin aiki yana da mahimmanci don rage suturar silima. Karfafa tabbatar da "matattarar uku" muhimmin ma'aunin inji don hana silinda na injina, wanda yake da matukar muhimmanci a cikin injin din. Ba daidai ba ne cewa wasu direbobi ba sa shigar da matattarar iska don a ceci mai.

4. Rike injin a zazzabi na yau da kullun

Zazzabi na aiki na yau da kullun na injin ya kamata ya zama 80-90 ° C. The zazzabi ya yi yawa kuma ba zai iya kula da abubuwan da ke cikin siliki ba, kuma sanya kayan acidic ɗin da ke cikin lalata da sutura. Gwajin ya nuna cewa lokacin da bangon waya bango ya rage daga 90 ℃ zuwa 50 ℃, silinda ya zama sau 4 da 90 ℃. Zazzabi ya yi yawa, zai rage ƙarfin silinda, zai iya haifar da suturar, kuma yana iya haifar da piston don ɗaukar piston don haifar da "fadada Silinda" haɗari.

5. Inganta ingancin garantin

Yayin aiwatar da amfani, ana samun matsaloli a lokacin da za a kawar da shi cikin lokaci, da lalace da lalacewar sassa ana maye gurbin ko gyara a kowane lokaci. Lokacin shigar da silima ainin silin, bincika kuma tara tsananin tsananin gwargwadon bukatun fasaha. A cikin garanti na garanti aiki, da ya kamata a zaɓi a cikin abubuwan da suka dace tare da ya kamata ƙarami, don haka gas ya fashe a cikin bango na silinda, ƙara mai jikin silinda. Yawan wuce gona da iri kai tsaye yana ƙara ɗaukar suturar silinda, ko suturar man fim ɗin mai a kan bango na silinda.

Crankshaftita Haɗa Rod Jarida da Babban Jarida Jarida ba ta da layi daya. Sakamakon tile tayal da sauran dalilai, crankhaft zai ƙazantar da mummunar tasiri, kuma idan ba a gyara shi ba, zai ci gaba da amfani da kayan silima.

Lokaci: Jul-30-2024